Let’s be honest, electrical drawings are one of those things everyone knows are important… right up until the day you desperately need them.

A motor trips, production stops, someone asks “which breaker is feeding that skid?”, and suddenly the site is running on guesswork, half-memories, and a faded folder that hasn’t been updated since the last big shutdown. Sound familiar?

Over the past few months, we’ve seen a sharp rise in requests from clients across multiple industries asking for one simple thing:

“Can you come in and tell us what we’ve actually got?”

Sometimes that means checking whether the electrical documentation matches reality. Other times, it means building the documentation from scratch because there isn’t any. Either way, if you’re responsible for safety, uptime, compliance, or future expansion, electrical “as built” accuracy is the foundation.

In this article, we’ll break down what “as built” really means, why it matters, what typically goes wrong on real sites, and how IDEA helps you get to a clear, compliant, maintainable set of documentation.

Why “As Built” Electrical Documentation Matters

Think of your electrical drawings like a map. If the map is wrong, it’s worse than having no map at all, because it creates confidence in the wrong decisions.

And in electrical systems, wrong decisions can mean:

- safety incidents,

- compliance issues,

- major downtime,

- damage to equipment,

- costly project delays.

Let’s unpack the big reasons.

Safety, compliance, and duty of care

If you operate a site, you’re expected to manage electrical risk properly. That includes knowing what’s installed, how it’s protected, and whether it meets current standards.

When drawings are missing or outdated, it becomes harder to prove that:

- circuits are correctly protected,

- disconnection times are met,

- cable sizing is suitable,

- modifications haven’t introduced hazards.

Even worse, engineers and technicians may end up working with assumptions instead of facts. And electricity is not forgiving.

Faster troubleshooting and less downtime

In operations, time matters. When a line is down, you don’t want a detective story. You want answers.

Accurate as-built drawings mean:

- faults are isolated faster,

- maintenance teams can plan work confidently,

- shutdown scope is clearer,

- contractors spend less time “finding out” and more time fixing.

In simple terms: good drawings reduce downtime and reduce stress.

Common Scenarios We See on Industrial Sites

Every site has a story. Here are some of the most common ones we’re seeing right now.

No drawings at all

Yes, this still happens. More often than you’d think.

It’s common on older sites, or sites that have changed hands, or sites where the “documents” are a mixture of partial PDFs, old prints, and sketches kept in someone’s drawer.

And when there’s no baseline, even small changes become risky because nobody can reliably say what’s connected to what.

Expansion plans but unknown spare capacity

A lot of sites are expanding production right now—new packaging lines, new process skids, new utilities, electrification projects, heat pumps, additional pumps, compressors, you name it.

But here’s the catch: many sites don’t truly know whether the existing electrical infrastructure can handle new demand.

So projects start with big questions:

- Is the main incomer sized appropriately?

- Are the distribution boards already near their limit?

- Are protective devices coordinated properly?

- Will volt drop become an issue?

- Will new loads upset discrimination and create nuisance trips?

If you can’t answer those early, expansion becomes slower, more expensive, and more uncertain.

Retirement risk: knowledge leaving the business

One scenario we’ve seen first-hand: the site electrical engineer was retiring, and they held an incredible amount of site knowledge in their head.

They knew:

- what had been modified,

- what had been “temporary” for five years,

- where cables actually run,

- which drawings are “sort of right if you squint”.

When that person leaves without capturing the knowledge, the site doesn’t just lose a colleague—it loses control of the electrical system story.

Mismatched drawings vs reality after years of changes

Sites evolve. That’s normal.

But over time, the “as built” file can drift away from what’s physically installed, especially if:

- changes were done under time pressure,

- contractors didn’t update documentation,

- temporary supplies became permanent,

- boards were modified without full re-checking.

It’s like renovating your house for 10 years but still using the original floor plan. Eventually, the drawing becomes fiction.

What an Electrical Site Survey Actually Covers

A proper electrical survey isn’t a quick walkaround with a clipboard. Done properly, it’s a structured verification of what’s installed, how it’s protected, and how it behaves as a system.

Verification from incomer to final circuits

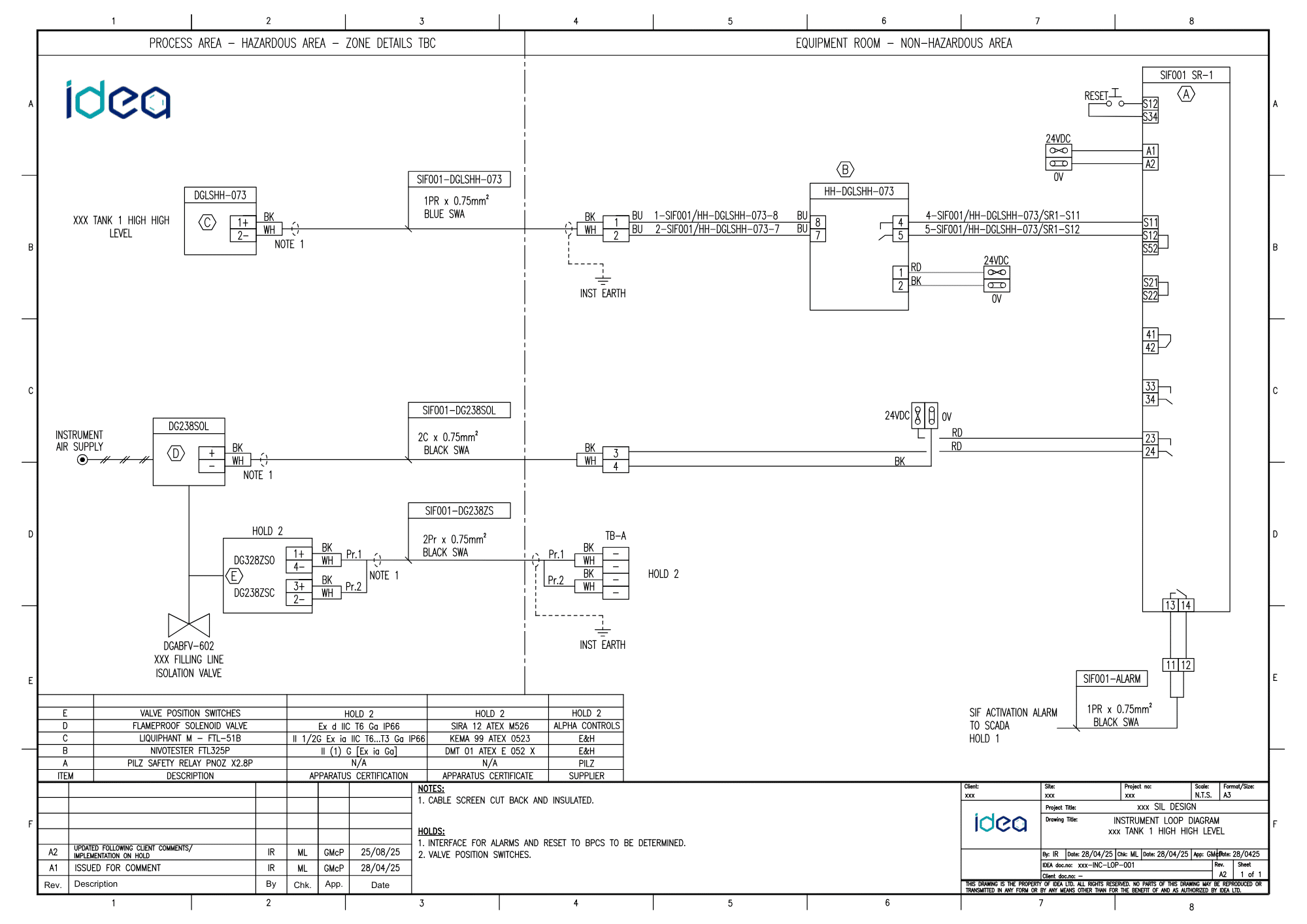

At IDEA, we can build and verify your electrical network from:

- the main incomer,

- through distribution,

- down to final circuits feeding equipment.

That includes gathering the right site data—ratings, settings, cable details, board schedules, and how loads are actually connected.

Confirming protective devices, cable routes, and load assumptions

We don’t just list components. We check the engineering logic behind them:

- Are protective devices correctly selected?

- Are cable sizes and installation assumptions valid?

- Are routes and lengths realistic?

- Are board schedules accurate?

- Do the drawings represent what’s physically there?

This is where the real value sits, because it’s the difference between “documentation” and “assurance”.

Our 18th Edition Electrical Modelling Approach

Here’s where things get practical and powerful.

IDEA uses an 18th Edition electrical software package that allows us to build your full electrical network and test it against key design checks.

It’s like running a “health check” on your electrical system—based on actual network structure, not generic assumptions.

Disconnection time and protective device suitability

Disconnection time isn’t just theory. It’s a safety requirement.

We check whether your protective devices will disconnect within the required times under fault conditions, based on:

- circuit parameters,

- fault levels,

- protective device characteristics.

Cable sizing, volt drop, and earth fault loop impedance

We check the essentials that often hide problems:

- cable CSA suitability,

- cable length impacts,

- volt drop compliance,

- earth fault loop impedance (Zs) checks.

These are the things that can quietly become non-compliant after years of modifications or load changes.

Discrimination and coordination (upstream/downstream)

Ever had a fault on one circuit trip a much bigger breaker upstream taking out a whole area?

That’s a coordination issue.

We assess discrimination between upstream and downstream protective devices so that faults are cleared as locally as possible, reducing disruption and improving reliability.

What You Get: Deliverables That Your Team Can Use

We’re big believers in leaving you with something useful, not a report that sits on a shelf.

A clear report with critical issues prioritised

Our report highlights:

- critical errors and non-compliances,

- risks to safety and reliability,

- improvement actions,

- priorities (so you know what to fix first).

It’s written so that engineering, maintenance, and management can all understand the “so what”.

Updated CAD ‘as built’ drawings

You receive a full set of updated “as built” drawings in CAD format, so your team can:

- maintain changes going forward,

- integrate future projects properly,

- reduce reliance on tribal knowledge.

A model you can maintain going forward

Where appropriate, we can leave you with a structured network model that becomes your baseline for:

- future plant additions,

- board modifications,

- compliance reviews,

- capital planning.

It turns “unknown” into “managed”.

Greenfield, Brownfield, and Plant Upgrades: How We Support You

Different sites need different approaches. We support clients across all of these scenarios.

New sites

For greenfield projects, the focus is building robust design and documentation from day one so you don’t inherit problems later.

Adding new plant and utilities

When you’re adding new equipment, we help you confirm:

- capacity,

- protection suitability,

- coordination,

- compliance,

- documentation alignment.

So your project doesn’t get derailed halfway through procurement or installation.

Brownfield modifications and compliance assurance

Brownfield sites are where “as built” accuracy matters most, because the site history is complex.

We help you get confidence that what’s installed is:

- safe,

- compliant,

- reliable,

- and documented properly.

How to Tell If Your Drawings Are Out of Date

Not sure where you stand? Here are some quick warning signs:

Simple warning signs you can spot quickly

- Drawings exist, but nobody trusts them.

- Labels in the field don’t match the schedule.

- You find “temporary” supplies that look permanent.

- Protective devices have been changed without recalculation.

- New loads have been added over time with no review.

- Expansion projects keep stalling at the “electrical unknowns” stage.

- Faults trip upstream devices more often than they should.

If you’re nodding along to even two of those, it’s worth investigating.

Why IDEA

You don’t want a box-ticking exercise. You want clarity and confidence.

Practical engineering, not box-ticking

We focus on real-world outcomes:

- safer systems,

- fewer surprises,

- better reliability,

- compliant documentation you can actually maintain.

Collaboration with operations, maintenance, and EHS

Electrical systems aren’t just engineering objects—they’re operational realities.

We work with your teams to understand:

- how the plant runs,

- what downtime costs,

- what access constraints exist,

- what future plans are coming.

That makes the outputs more accurate and more useful.

Next Steps: Speak to Our Lead EC&I Engineer

If you’re unsure about the current status of your electrical drawings or you want assurance before expanding, modifying, or upgrading, let’s talk.

IDEA can help you review your design and documentation, identify issues, and provide updated “as built” CAD drawings along with a clear report highlighting any critical errors within your network.

To find out more, contact our lead EC&I engineer: Craig Berry

What to prepare before the first call

If you have them, it helps to share:

- any existing single line diagrams,

- board schedules,

- previous test results (if available),

- details of planned expansions or new loads,

- known problem areas (nuisance trips, downtime events, etc.).

Don’t worry if you don’t have everything, we can still guide the right next step.

Conclusion

If your “as built” electrical drawings are out of date, incomplete, or missing, you’re essentially running your site with a blurred dashboard. You might still be moving forward but you’re doing it with unnecessary risk and avoidable uncertainty.

The good news? Getting control doesn’t have to be painful. With the right site survey, a structured 18th Edition modelling approach, and updated CAD documentation, you can turn electrical unknowns into a reliable baseline for safety, uptime, and future expansion.

If you’re planning changes, or you simply want confidence that what you have is compliant and accurately documented, IDEA can help you get there.

FAQs

1) What does “as built” mean for electrical drawings?

“As built” means the drawings reflect what is actually installed on site, not what was originally designed. It includes changes made during construction, modifications over time, and any deviations from the original plan.

2) Can you help if we have no electrical drawings at all?

Yes. We can carry out a site survey, capture the installed system, and produce a full set of “as built” CAD drawings along with checks to support compliance and future maintenance.

3) Do you only work on large industrial sites?

No. We support a wide range of sites and industries from smaller facilities to complex multi-board industrial plants. The approach scales to the site need.

4) What’s the benefit of modelling the network using 18th Edition software?

It allows the electrical network to be checked from incomer to final circuits for key compliance items like protective device suitability, disconnection time, volt drop, earth loop impedance, cable sizing, and discrimination.

5) When should we do an electrical documentation review?

Common trigger points are: before adding new plant, during expansion planning, after repeated trips/downtime events, when key personnel are leaving, or when you suspect drawings no longer match reality.