Centrifugal pumps are one of the most common pieces of rotating equipment and they are widely used in the whisky and chemical process industries for transferring liquids of varying viscosity, pressure and temperature. Correct specification of a centrifugal pumps is crucial for ensuring safe and efficient process plant operation. In this article, we will discuss some of the factors that need to be considered while selecting a centrifugal pump for process industry applications.

Operating Points:

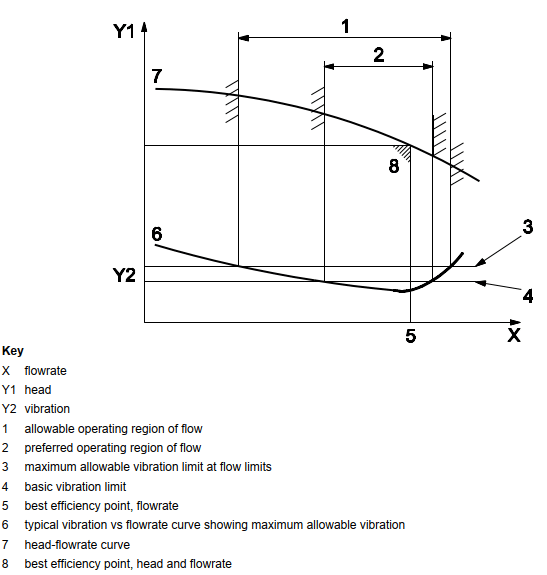

It is crucial that centrifugal pumps operate within the preferred operating envelope to keep operating costs low, and efficiency high. Pumps that run away from the intended duty point and allowable operating region can lead to a significant increase in energy costs due to inefficient operation and can also suffer significant reliability problems. Therefore, it is important to understand where the pump operates and how it interacts with the system resistance curve.

Chemical Compatibility / Materials of Construction:

The chemical compatibility of the pump’s wetted parts is of critical importance. The selected material must be resistant to the chemical being pumped. The chemical may cause corrosion or erosion in the pump, leading to reduced efficiency or even catastrophic failure. Therefore, the pump’s wetted parts, such as impellers, casing, and shaft and seals must be made of materials that can withstand the chemical’s properties. Common materials used are low alloy steels, stainless steels, thermoplastics and elastomers.

Testing

It is critical that centrifugal pumps are tested prior to installation. Testing can include the non-destructive testing to ensure manufacturing processes have been carried out successfully. Hydrostatic testing to ensure casings are suitably designed and manufactured and performance testing to ensure that the pump performance can be proven to be in accordance with the theoretical performance curves. Mechanical run tests can also be carried out to prove pumps will operate continuously within acceptable vibration and temperature tolerances.

Quality Assurance

Quality assurance is of utmost importance in the manufacture of centrifugal pumps. Any defects or malfunctions in a pump can have serious consequences, leading to production downtime, safety hazards from loss of containment, and costly repairs. Therefore, manufacturers must have rigorous quality control processes in place to ensure that their pumps are built to the highest standards of quality and reliability. Ensuring manufacturers operate a Quality Management System in accordance with the requirements of BS EN ISO 9001 can ensure that their centrifugal pumps will perform as intended, minimizing the risk of failures. The manufacturers inspection and test plans define the quality management activities required during all stages of design, procurement, fabrication, assembly, testing and despatch.

Maintenance:

Maintenance is an important factor to consider in pump selection. Centrifugal pumps require regular maintenance to ensure that they are working correctly. The ease of maintenance of a pump is an important factor to consider. Pumps with simple designs and easy access to internal components make maintenance easier and more cost-effective. When installing a centrifugal pump in a process plant, appropriate space must be allocated to allow for maintenance of the pump and motor. Reducing maintenance requirements can significant improve plant uptime and reduce operating costs.

IDEA:

Selecting the right centrifugal pump for chemical applications can be challenging. It is always recommended to seek advice from experts in the field to ensure that the pump selection is appropriate for the specific chemical process. At IDEA we have experienced process, mechanical and electrical engineers who have vast expertise in centrifugal pump sizing, selection, specification, installation and commissioning.