Why functional safety is suddenly on everyone’s agenda

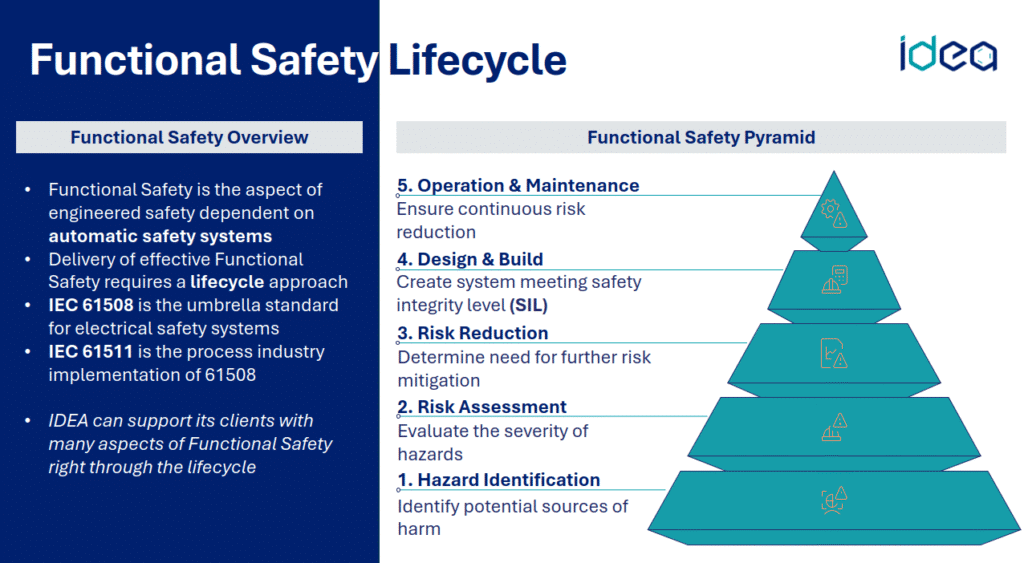

If you operate in a high hazard industry, functional safety is no longer a “nice to have.” It’s one of the biggest ongoing compliance priorities, and for good reason. A well designed Safety Instrumented System can be the difference between a controlled shutdown and an incident that becomes a headline.

But here’s the part that often gets missed. Functional safety is not just a pile of paperwork. It’s a practical engineering discipline that has to work on real plants, with real operators, real maintenance constraints, and real production pressures. If it is not usable, it will not be used. And if it is not used, it will not protect you.

At IDEA, we support clients across multiple sectors with functional safety design and delivery. We bring process safety and functional safety together, so the SIS that gets specified is the SIS that actually makes sense.

Where we start: hazard identification and initial risk assessment

HAZID, HAZOP, and LOPA that lead to clear decisions

Functional safety starts upstream. Before anyone talks about SIL, sensors, logic solvers, or shutdown valves, we need to understand the hazards and the risk.

Our independent process safety team routinely facilitates and supports:

HAZID studies

Early stage hazard identification to shape the design direction, highlight showstoppers, and set priorities.

HAZOP studies

Structured review of process deviations, safeguards, operability challenges, and actions required to reduce risk.

LOPA studies

Where needed, we support Layer of Protection Analysis to confirm whether a Safety Instrumented Function is required, and what level of risk reduction it must deliver.

When these studies demonstrate that a Safety Instrumented Function is required as a risk reduction measure, our in house Functional Safety Engineers step in to help design, document, and implement a robust SIS solution end to end.

From “we need a SIF” to “we have a defensible SIS”

The SIS lifecycle can feel like a maze

A lot of teams know the feeling. You have a HAZOP action saying “Consider SIF.” Then you are suddenly deep in debates about SIL targets, proof test intervals, device selection, and whether your existing DCS can do the job.

It can get messy fast.

Our approach is simple. We help you translate process risk decisions into a functional safety design package that is:

- Clear enough for operations

- Detailed enough for engineering

- Auditable enough for compliance

- Practical enough to maintain

What we deliver: core functional safety packages

Below is the type of support we routinely provide. You can engage us for a full lifecycle package or for a specific workstream.

Safety Requirements Specification

The SRS is the backbone of your SIS

If the SRS is weak, everything downstream becomes guesswork. We develop Safety Requirements Specifications that clearly define:

SIF intent and demand scenarios

What event triggers the SIF, how often it can be expected, and what “success” looks like.

Functional requirements

Trip setpoints, voting, logic, permissives, resets, bypass rules, and required actions.

Performance requirements

SIL target, response time, proof test intervals, diagnostics, and constraints.

Interfaces and dependencies

How the SIF interacts with BPCS, alarms, interlocks, utilities, ESD hierarchy, and cause and effect philosophy.

Cause and Effect charts for SIFs

No ambiguity when it matters most

Cause and Effect charts are where clarity wins. We develop Cause and Effect charts for all SIFs so everyone, from engineers to operators, is aligned on:

- What initiates a trip

- What outputs must act

- What alarms and indications occur

- What reset conditions apply

SIF loop diagrams

Make installation and maintenance easier

SIF loop diagrams are a practical deliverable that reduces mistakes. They give your teams a single source of truth for:

Signal paths

From sensor to logic to final element.

Terminations and interfaces

Panels, marshalling, junction boxes, and network boundaries.

Test points and isolation

So proof testing does not become a risky improvisation.

Proof test procedures

A SIF is only as good as its proof testing

Proof testing is where theory meets reality. We develop proof test procedures that are:

- Safe to execute

- Clear and step based

- Realistic for site teams

- Aligned with the assumptions used in SIL verification

And we do not just write procedures and walk away. We help teams understand them, improve them, and use them.

SIL verification calculations and reports

The numbers must match the story

SIL verification should not be a black box. We produce SIL verification calculations and reports, including approval packs, that clearly show:

Assumptions

Proof test intervals, coverage, partial stroke testing, common cause, and bypass durations.

Device data

Failure rates, diagnostic coverage, and certificates.

Results

PFDavg or PFH outcomes, margin, and what needs to change if the target is not met.

Instrument datasheets and failure rate data certificates

Good data in means credible verification out

We support instrument datasheets and ensure the failure rate data being used is appropriate, traceable, and defensible. This is one of those areas where shortcuts often come back later as painful questions in audits.

URS inputs for software and SIS engineering

Procurement and delivery get easier when the URS is right

If you are procuring SIS engineering, software configuration, or packaged system modifications, we provide URS inputs so suppliers know exactly what is expected, and your project avoids scope creep and rework.

Functional Safety Assessments (FAS2 and FSA3)

We support Functional Safety Assessments, including:

FSA2

Typically aligned with design and implementation readiness, checking the SIS is being developed to meet the requirements and lifecycle expectations.

FSA3

Typically aligned with commissioning and validation, ensuring the SIS has been built, tested, and proven in line with the SRS.

Our goal is to make assessments constructive. Not scary. Not vague. Just solid engineering evidence that stands up to scrutiny.

SIS Software FAT and Site SAT support

Testing that proves what matters

We support SIS Software FAT and site SAT and verification, helping you confirm:

- Logic matches the SRS

- Cause and effect is implemented correctly

- Bypass and reset rules are safe and controlled

- Testing records are complete and auditable

- Site interfaces behave as expected

This is where functional safety becomes real. We help you get it right before startup pressure kicks in.

When regulators raise concerns: calm, evidence led responses

Turning scrutiny into a structured plan

Sometimes the challenge is not designing a new SIS. It is responding when regulators raise concerns about what already exists.

We have supported clients in these situations by helping them respond with:

- Clear engineering evidence

- Practical actions that can be implemented on real sites

- A defensible functional safety strategy that fits the plant and the organisation

Think of it like turning a pile of loose threads into a stitched together narrative. Evidence, gaps, actions, ownership, and timelines. No drama. Just solid engineering.

Why we invested in exSILentia

Consistency and auditability without the pain

To strengthen our capability further, we have invested in Exida’s exSILentia software to support consistent, auditable verification and lifecycle documentation.

That means better traceability, better repeatability, and fewer “spreadsheet mysteries” when someone asks how a number was derived.

What makes IDEA’s approach different

We join the dots between process safety and functional safety

Functional safety works best when it is not isolated. Our process safety and functional safety teams work together, which helps ensure:

- The SIF is justified by the hazard studies

- The SIL target matches the risk decision

- The design is practical for operations and maintenance

- The documentation stands up in audits and assessments

We design for reality, not for a perfect world.

How you can engage us

Whether you need initial assessments, a specific SIL design package, FSA support, or a site wide functional safety strategy and training, we can help.

Typical engagement options

Option 1: Early stage risk to SIF definition

HAZOP and LOPA support through to initial SIF register and SIL targets.

Option 2: SIF and SIS design package

SRS, Cause and Effect, loop diagrams, verification, and proof testing deliverables.

Option 3: Delivery and testing support

FAT and SAT support, validation evidence, and commissioning readiness.

Option 4: Assurance and improvement

FSA2 and FSA3 support, gap assessments, and regulator response packs.

Get in Touch

If you need functional safety support, speak to Gary McPhillie, Ravindra Marathe, PhD, or Craig Berry. We’ll help you turn functional safety from a compliance headache into a clear, workable engineering system that protects your people, your plant, and your production.

FAQs

1. When do I actually need a Safety Instrumented Function

You typically need a SIF when your existing protection layers do not reduce risk enough, and a specific instrumented action is required to achieve tolerable risk.

2. What is the biggest mistake teams make with the SRS

Being vague. If the SRS does not clearly define what the SIF must do, how fast it must act, and how it must be tested, everything downstream becomes uncertain.

3. Can you help if we already have an SIS in place

Yes. We can review existing SIFs, verify SIL performance, improve proof testing, support FSAs, and help respond to regulator questions with evidence and actions.

4. Do you only work in one industry

No. We have supported clients across multiple sectors in high hazard environments where functional safety and SIS compliance are critical.

5. How do we get started

Start with a short call. We can understand your drivers, where you are in the lifecycle, and propose the most efficient route, whether that’s a focused SIL package or a broader site wide strategy.